Carbon Capture & Storage (CCS)

Carbon capture and storage technologies are increasingly used across industries to reduce CO₂ emissions that cannot be avoided through fuel switching or process changes. In the power sector, carbon capture systems are integrated with existing coal, gas, and biomass plants to capture CO₂ directly from boilers and turbines. In cement and lime production, where calcination releases unavoidable process emissions, carbon capture offers one of the only viable solutions to reduce the sector’s carbon footprint. Similarly, iron and steel plants apply carbon capture to blast furnace gases, while chemical industries and oil refineries target high-purity CO₂ streams and flue gases from process heaters and other units.

Looking forward, carbon capture and storage (CCS) will also be essential for producing low-carbon hydrogen, which is critical for sustainable fuels in aviation and shipping. Additionally, when combined with bioenergy (BECCS), carbon capture enables negative emissions—removing CO₂ from the atmosphere rather than simply reducing new emissions.

Research and development efforts continue to improve capture performance and reduce costs. Current focus areas include optimizing solvents and sorbents, controlling aerosol and particulate formation, integrating systems with heat recovery, and scaling up technologies for industrial deployment. As industries pursue decarbonization and net-zero goals, carbon capture technologies are becoming a key enabler of long-term climate strategies.

Dekati Aerosol Measurement Solutions for CCS

Aerosol characterization is essential in carbon capture and storage (CCS) for both understanding flue gas conditions and ensuring efficient, reliable plant operation. Accurate measurement of aerosol concentration and particle size distribution is needed before designing or applying any CO₂ capture technology—be it absorption, adsorption, or membrane-based.

As flue gas cools during the capture process, acid aerosols (e.g. from sulfuric acid condensation) may form. These can cause corrosion, reduce efficiency, and impact material selection. Monitoring aerosol formation helps prevent equipment damage and supports better design choices.

In advanced CCS systems, aerosols also influence performance. Adsorption systems may release fine sorbent particles into the gas stream, while membrane systems can suffer from aerosol-related fouling and chemical degradation, reducing efficiency and membrane life.

After CO₂ is captured, gas purity becomes critical for transport, storage, or reuse. Trace aerosols and acidic compounds can compromise CO₂ quality and accelerate corrosion, especially under high pressure where the acid dew point increases. Comprehensive aerosol monitoring ensures the captured CO₂ meets purity standards and is safe for long-term storage or industrial use.

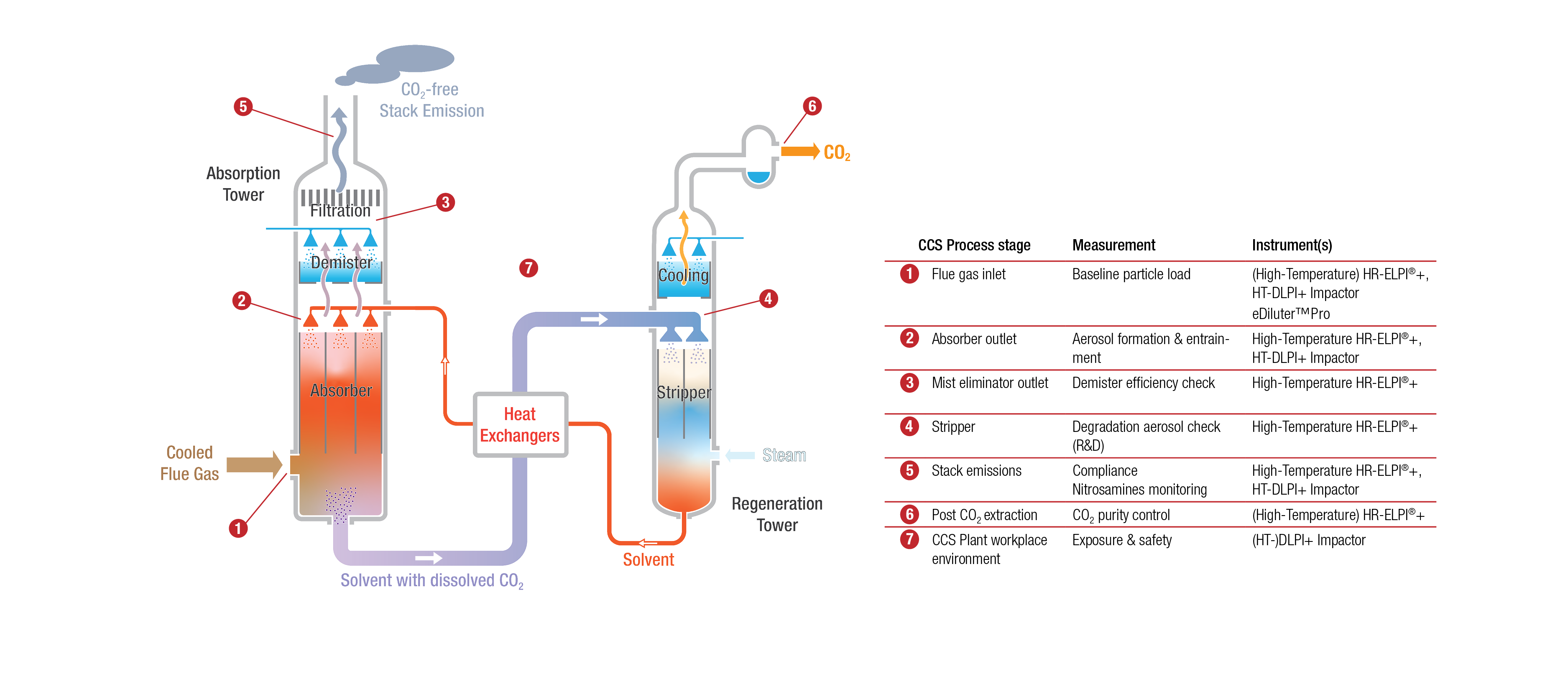

The schematic below shows the various Dekati aerosol measurement solutions for use in CCS process control and optimization:

Real-time Aerosol Measurement Solutions

The Dekati® High-Temperature HR-ELPI®+ system provides real-time measurement of particle concentration and size distribution across a range of 6 nm to 10 μm, with size classification into 14 to 500 size classes at a 10 Hz time resolution. It is a unique instrument capable of measuring high temperatures (up to 180 °C) and humid aerosols without dilution, allowing measurements without the risk of sample transformations regardless of the particle concentrations. These features make the High Temperature version of the HR-ELPI®+ the perfect choice for aerosol measurements in the different CCS process stages.

Gravimetric Measurement Solutions

The DLPI+ (Dekati® Low Pressure Impactor) is a 14-stage cascade impactor that is used to determine airborne particle mass size distribution into 13 size fractions in the range of 16 nm – 10 μm. The particles are collected on collection substrates that are weighed before and after the measurement to obtain gravimetric size distribution of the particles, and allow a post-measurement chemical or microscopical analysis. The High-Temperature version of the DLPI+ can be heated up to 180 °C for direct sampling of high temperature aerosols.

Dilution Systems

The Dekati® eDiluter™ Pro is an advanced, portable, dilution system that allows easy sample conditioning for a wide range of particle measurement applications. Its compact structure includes a two-stage dilution system with an adjustable total dilution factor ranging from 1:25 to 1:900. Diluted sample can also be extracted directly after the first dilution stage.